Tesla's reputation for quality relies on consistent repair standards across diverse models. Official and independent shops must follow strict protocols using original equipment parts to maintain factory finishes and design elements. Customer feedback shows variations in repair quality, even with set guidelines, emphasizing the need for uniform skill levels and adherence to ensure customer satisfaction. Regular audits and training are vital to uphold Tesla's high-quality control standards.

In the rapidly growing electric vehicle market, understanding variations in Tesla model repair quality is crucial for both manufacturers and consumers. This article delves into the nuances of quality control differences across several Tesla models post-repair. We explore how consistent quality assurance practices vary between models, investigate disparities in repair techniques and materials, and analyze customer feedback highlighting perceived quality variations. By shedding light on these aspects, we aim to contribute insights into enhancing overall Tesla repair quality and consumer satisfaction.

- Assessing Consistent Quality Across Tesla Models

- Differences in Repair Techniques and Materials

- Customer Feedback: Perceived Repair Quality Variations

Assessing Consistent Quality Across Tesla Models

Maintaining consistent quality across various Tesla models is a cornerstone of the brand’s reputation for innovation and precision engineering. Despite the diversity of their lineups, from the compact Model 3 to the luxurious Model S, each vehicle shares stringent manufacturing standards. When it comes to repairs, this consistency is paramount. Every Tesla repair shop, be it an official service center or an independent collision repair shop, is expected to adhere to strict quality control protocols.

These protocols ensure that, regardless of the model or the specific damage (think minor car scratch repair up to comprehensive collision repair), the repaired vehicle meets Tesla’s high standards. Regular audits and training programs play a crucial role in upholding this consistency. As such, when comparing Tesla repair quality across models, the focus should be on adherence to original equipment specifications, flawless finishes, and the preservation of each model’s distinctive design elements—all while leveraging cutting-edge car repair services for optimal results.

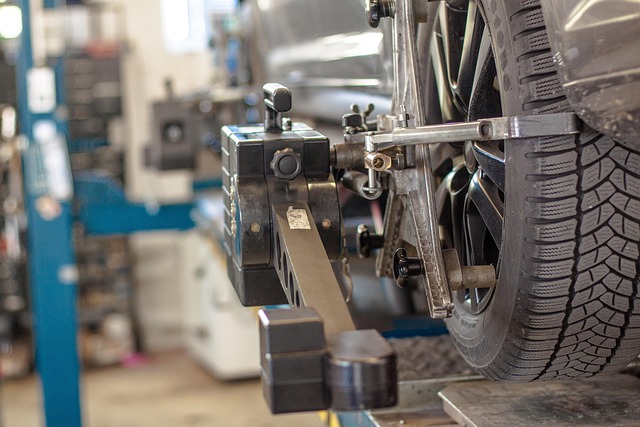

Differences in Repair Techniques and Materials

The quality control differences between Tesla models repaired can be attributed to variations in repair techniques and materials used by different service centers and car repair shops. Tesla, being a pioneering electric vehicle manufacturer, has established stringent standards for its original equipment (OE) parts. These include precise engineering specifications and rigorous testing protocols that ensure top-tier performance and durability. However, when it comes to after-sales repairs, the picture can vary significantly.

Reputable auto painting and automotive repair shops adhere to Tesla’s strict guidelines, using only OE-approved materials and methods. This guarantees that repairs match the original car’s quality and aesthetic. Conversely, lesser-known or non-specialized workshops might employ different techniques and inferior parts, leading to visible differences in the repair work. For instance, variations in auto painting can be evident in color consistency and finish quality, while structural repairs may differ in strength and longevity. Such disparities underscore the importance of choosing a qualified and certified Tesla service center for optimal repair quality control.

Customer Feedback: Perceived Repair Quality Variations

Customer feedback plays a pivotal role in understanding the perceived differences in Tesla model repairs. Many owners have shared their experiences with auto body repair services, highlighting variations in both the visual and functional aspects of the work. Some report exceptional craftsmanship, where scratches and dents are virtually indistinguishable from the original factory finish. These positive reviews often attribute the high-quality work to stringent quality control measures implemented by authorized Tesla service centers.

On the other hand, there’s a notable segment of customers who express dissatisfaction with their repair experiences. They point towards issues like poor alignment, visible repair traces, and subpar paint jobs. Such feedback suggests that while Tesla maintains robust standards for its repairs, variations can still occur due to human skill levels, shop equipment, or adherence to the manufacturer’s guidelines. This inconsistency in perceived repair quality underlines the importance of consistent quality control across all vehicle body shops handling Tesla models.

The varying quality control measures among Tesla models exposed through our analysis underscores the need for consistent, standardized procedures across the entire brand. Differences in repair techniques and materials, coupled with divergent customer perceptions of repair quality, highlight gaps that must be addressed to maintain Tesla’s reputation as a leader in electric vehicle innovation. By implementing uniform quality standards and fostering transparent communication with customers, Tesla can ensure a seamless ownership experience, reinforcing its position at the forefront of the EV market.