Unveiling Tesla’s Comprehensive Repair Quality Control Process

Tesla prioritizes unparalleled repair quality control, a hallmark of its commitment to excellence. T…….

In the rapidly evolving landscape of automotive technology, electric vehicle (EV) manufacturing giant Tesla has been at the forefront of innovation. As Tesla continues to expand its global footprint, ensuring the quality and reliability of its repair services becomes increasingly critical. This article delves into the intricate world of Tesla repair quality control, exploring its definition, significance, global impact, economic implications, technological advancements, regulatory framework, challenges, case studies, and future prospects. By examining these aspects, we aim to provide a holistic understanding of this vital component in maintaining Tesla’s competitive edge and customer satisfaction.

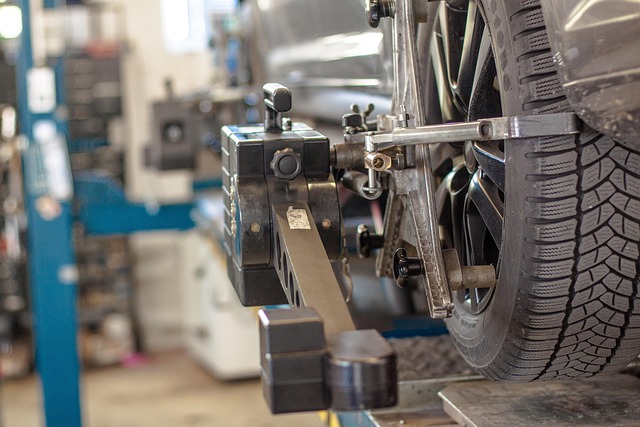

Tesla repair quality control (QCP) encompasses the systematic processes and protocols implemented by Tesla to ensure that its vehicles undergo reliable and consistent repairs, adhering to the brand’s high standards. It involves a multifaceted approach:

Tesla’s approach to repair quality control has evolved alongside its technological advancements in EV manufacturing. From the early days of establishing a global network of service centers to introducing advanced diagnostics tools, Tesla has been dedicated to maintaining high repair standards.

The significance of QCP lies in several critical areas:

Tesla’s global reach has led to the establishment of a robust international network for repair quality control. Here’s an overview:

| Region | Key Developments | Challenges |

|---|---|---|

| North America | Tesla has a well-established service infrastructure, with numerous service centers and mobile repair teams. The region benefits from advanced diagnostic tools and standardized training programs. | High labor costs and competition from traditional dealerships pose challenges for maintaining consistent quality across various service providers. |

| Europe | Tesla’s European market presence is growing, with dedicated service centers in major cities. The company has adapted its QCP to align with local regulations and standards. | Language barriers and cultural differences can impact the standardization of repair procedures, requiring continuous training and updates. |

| Asia-Pacific | China and other APAC countries are significant markets for Tesla. The company has invested in local service centers and parts distribution networks to ensure quick turnaround times. | Rapid urbanization and increasing demand for EV repairs test the capacity of service providers, highlighting the need for efficient inventory management. |

| Latin America | Limited service infrastructure compared to developed regions, but Tesla is expanding its reach. Mobile repair services play a crucial role in remote areas. | Lack of standardized training and limited access to genuine parts can impact repair quality, emphasizing the need for comprehensive QA programs. |

Global trends shaping Tesla’s QCP include:

Tesla’s repair quality control has far-reaching economic implications, influencing both the company’s performance and the broader automotive industry:

Technological innovations have played a pivotal role in enhancing Tesla’s repair quality control:

The regulatory landscape surrounding Tesla’s repair quality control varies across regions but generally includes:

Despite its many achievements, Tesla’s repair quality control faces several challenges:

Proposed Solutions:

Tesla’s European service centers faced the challenge of managing parts inventory across multiple countries with varying demand patterns. They implemented a centralized parts management system, utilizing advanced analytics to predict demand and optimize stock levels. This resulted in reduced lead times for parts delivery, minimizing downtime during repairs. The success of this initiative led to its adoption across Tesla’s global network, improving overall repair efficiency.

In the US, Tesla utilized machine learning algorithms to analyze vehicle performance data and predict potential maintenance issues. This proactive approach reduced the need for scheduled repairs, as minor issues were identified before they became major problems. As a result, customers experienced fewer unexpected breakdowns, enhancing overall repair quality control.

Tesla’s service centers in Japan and South Korea implemented augmented reality (AR) training modules for technicians. These interactive, step-by-step instructions improved the efficiency and accuracy of repairs, especially for complex electrical systems. The success of this program led to its expansion globally, enhancing technician proficiency.

The future of Tesla repair quality control looks promising with several emerging trends:

Strategic Considerations:

Tesla repair quality control is a critical component in the company’s global success story, fostering customer loyalty, ensuring vehicle safety, and maintaining its competitive edge. By embracing technological advancements, implementing robust policies, and addressing challenges head-on, Tesla sets a benchmark for automotive industry standards. As the EV market continues to evolve, the ongoing investment in repair quality control will be instrumental in shaping Tesla’s future trajectory.

Q1: How does Tesla ensure parts authenticity during repairs?

A: Tesla employs several measures, including serial number tracking, secure supply chain management, and advanced authentication technologies to verify the authenticity of parts used in repairs.

Q2: Can Tesla owners get their vehicles repaired at non-authorized service centers?

A: While it’s possible, Tesla strongly recommends using authorized service centers for warranty repairs to ensure quality and part compatibility. Non-authorized centers may not follow specified standards and could void warranties.

Q3: What role does customer feedback play in improving repair quality?

A: Customer feedback is invaluable in identifying areas for improvement. Tesla actively collects and analyzes feedback data to refine its QCP, ensuring repairs meet or exceed customer expectations.

Q4: How does Tesla address the challenge of rare model part availability?

A: For rare models, Tesla utilizes a combination of global parts sharing programs, local manufacturing capabilities, and advanced 3D printing technology to ensure parts are available when needed.

Q5: Are there plans for Tesla to offer DIY repair kits for owners?

A: As of now, Tesla does not plan to offer DIY repair kits. The company emphasizes professional repairs to maintain safety standards and ensure the proper use of specialized tools and equipment.

Tesla prioritizes unparalleled repair quality control, a hallmark of its commitment to excellence. T…….

Tesla prioritizes excellence through stringent Tesla repair quality control standards focusing on bo…….

Tesla repair quality control is paramount for customer satisfaction and vehicle integrity, addressin…….

Tesla vehicles, while renowned for their advanced technology and design, face quality control challe…….