Tesla's global service centers maintain high repair quality control through multi-stage inspections, extensive technician training, and standardized procedures. Independent assessments reveal inconsistencies compared to manufacturer standards, such as paint finish and panel alignment. Best practices like regular workshops, detailed repair procedures, digital tracking systems, and prioritizing technician skills ensure consistent top-tier repairs, enhancing Tesla's market reputation.

Tesla, a pioneer in electric vehicles, has revolutionized the automotive industry. However, ensuring consistent repair quality control across its vast global network remains a challenge. This article delves into Tesla’s repair quality control processes, highlighting the importance of independent assessments to uncover consistency gaps. By examining best practices from the broader automotive sector, we offer insights into enhancing repair accuracy and boosting customer satisfaction for this pioneering manufacturer.

- Examining Tesla's Repair Quality Control Processes

- Independent Assessments: Uncovering Consistency Gaps

- Best Practices for Enhancing Repair Accuracy & Customer Satisfaction

Examining Tesla's Repair Quality Control Processes

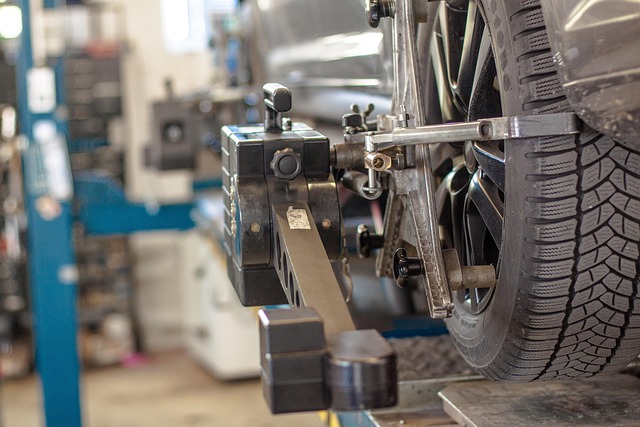

Tesla’s commitment to maintaining high standards in its repair quality control processes is evident across its global service centers. These procedures are meticulously designed to ensure that every vehicle leaving their facilities meets Tesla’s stringent criteria for performance and aesthetics. The process involves multiple stages, including a thorough inspection of both structural integrity and cosmetic details.

A key aspect of their approach is the emphasis on training and standardization. All technicians undergo extensive training in the latest repair techniques, with regular refresher courses ensuring they stay updated with industry advancements. This consistency in skill sets facilitates precise and uniform repairs, whether it’s addressing a dent repair or performing auto glass replacement. The comprehensive nature of these quality control measures instills confidence in customers that their vehicles are in capable hands during service and repair.

Independent Assessments: Uncovering Consistency Gaps

Independent assessments play a pivotal role in exposing any inconsistencies within Tesla’s repair quality control processes. These unbiased evaluations are crucial as they offer an outside perspective on what is often a tightly controlled internal operation. By comparing the outcomes of these independent reviews with the manufacturer’s standards, significant gaps in consistency can be identified.

Such assessments uncover potential areas where Tesla’s repair procedures might require enhancement or standardization. For instance, when comparing Mercedes-Benz collision repair services from various body shops, including Tesla’s authorized centers, discrepancies may arise in paint finish, panel alignment, and overall restoration accuracy. These findings underscore the importance of continuous improvement in quality control to ensure that every vehicle undergoes consistent, high-quality repairs, regardless of the service provider.

Best Practices for Enhancing Repair Accuracy & Customer Satisfaction

To enhance Tesla repair quality control and boost customer satisfaction, several best practices can be implemented. One key strategy is to prioritize training and education for technicians. Regular workshops and certifications ensure they stay updated with the latest industry standards and technological advancements in automotive body work and auto painting. This enables them to perform repairs with precision and use the right materials for each job.

Additionally, establishing detailed and standardized repair procedures can significantly improve accuracy. Consistent documentation and communication across all service centers help maintain high-quality standards. For fleet repair services, implementing digital systems for tracking repairs and ensuring quality checks at every stage can drive customer trust. By focusing on these practices, Tesla can consistently deliver top-tier repairs, fostering a positive reputation in the market.

A thorough third-party review of Tesla’s repair quality control efforts reveals both promising practices and areas needing improvement. By independently assessing consistency gaps, we identify best practices that can enhance repair accuracy and ultimately boost customer satisfaction. This analysis underscores the importance of continuous evaluation and optimization in maintaining Tesla’s reputation for excellence in vehicle repairs.