Tesla repair quality control is a paramount concern in the rapidly evolving EV industry. With advancing technology and rising consumer expectations, Tesla sets high standards for itself and its service centers, focusing on precise repairs for intricate electrical systems and software. Maintaining this quality ensures driver safety, customer satisfaction, and reinforces Tesla's reputation as an automotive leader. Embracing digital era technologies like advanced diagnostic systems and specialized equipment is crucial for achieving unparalleled accuracy and consistency in EV repairs.

In today’s rapidly evolving landscape of electric vehicle (EV) ownership, Tesla repair quality control has never been more critical. As standards rise and consumer expectations shift, ensuring meticulous repair processes is paramount for both brand reputation and safety. This article delves into the significance of stringent quality control measures in the context of Tesla repairs, exploring how these practices mitigate risks, foster trust, and leverage technology to meet the demanding needs of EV owners in a bustling market.

- Evolving Standards in Electric Vehicle Repair

- The Impact on Consumer Trust and Safety

- Embracing Technology for Enhanced Quality Control

Evolving Standards in Electric Vehicle Repair

In recent years, the standards for electric vehicle (EV) repair have evolved significantly, driven by the rapid advancement in technology and increasing consumer expectations. Tesla, a pioneer in the EV space, has set a high bar for itself and its service centers globally when it comes to Tesla repair quality control. This is not merely about fixing cars; it’s about ensuring every component, from intricate electrical systems to advanced software, functions seamlessly within the vehicle’s sophisticated network. As EVs become more integrated into daily life, the need for precise, efficient, and reliable repairs has never been greater.

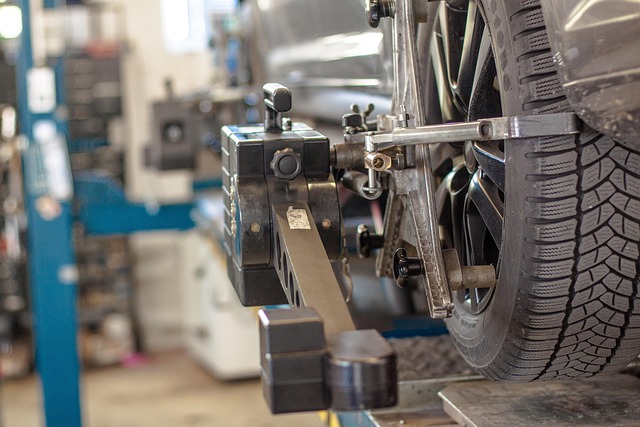

Gone are the days when basic automotive body work sufficed. Today’s vehicles, especially those produced by Tesla, require specialized knowledge and tools to handle everything from battery pack replacements to sophisticated sensor calibrations. Even tasks like tire services necessitate a deeper understanding of EV dynamics, as these vehicles have unique tire and suspension systems designed for optimal performance and efficiency. Customers no longer settle for less than perfect repairs; they expect the same level of quality control that Tesla implements in its manufacturing processes, ensuring their vehicles not only run smoothly but also maintain their advanced features and resale value.

The Impact on Consumer Trust and Safety

In today’s market, where consumer trust is paramount, Tesla repair quality control plays a pivotal role in shaping public perception and ensuring customer safety. A brand known for its innovative technology and forward-thinking approach must maintain rigorous standards when it comes to repairs. Poor quality control can lead to mistrust among owners, as the integrity of their vehicles may be questioned. Every repair, whether it’s a simple dent removal or complex fleet repair services, should be handled with precision and expertise.

When Tesla fails to uphold its reputation for superior quality, it risks impacting consumer confidence. Customers invest significant amounts in these electric vehicles, expecting them to perform not just adequately but exceptionally. Consistency in repair work, from hail damage repair to routine maintenance, is crucial to maintaining that expectation. Ensuring every fix is done right not only safeguards the safety of drivers but also reinforces Tesla’s image as a leader in both automotive technology and customer satisfaction.

Embracing Technology for Enhanced Quality Control

In today’s digital age, embracing technology is paramount for any industry aiming to excel in quality control, and Tesla repair quality control is no exception. The automotive sector has witnessed a paradigm shift with the introduction of advanced tools and software designed to enhance precision and efficiency in repairs. For Tesla vehicles, this means leveraging cutting-edge diagnostic systems and specialized equipment tailored to their unique electrical and mechanical components. By integrating these technological advancements, auto body repair shops and fleet repair services can achieve unprecedented levels of accuracy and consistency in their work.

This digital transformation not only streamlines the repair process but also enables comprehensive quality assessments. Advanced software can detect even the subtlest anomalies, ensuring every Tesla leaves the workshop in pristine condition. Moreover, these technological solutions facilitate data-driven decision-making, allowing shops to continuously improve their auto body services and stay ahead of industry trends. As a result, customers benefit from safer, more reliable vehicles, solidifying the reputation of Tesla repair quality control as an industry standard.

In today’s rapidly evolving electric vehicle landscape, Tesla repair quality control is more crucial than ever. As standards rise and consumer expectations increase, ensuring precise and safe repairs is vital to maintaining trust and retaining customers. Embracing advanced technology in quality control processes allows workshops to stay ahead, deliver consistent results, and meet the rigorous demands of modern EV ownership. Prioritizing Tesla repair quality control is not just a recommendation—it’s a necessity for long-term success in this expanding market.