Tesla's Repair Quality Control (TQQC) is a multi-step process ensuring every repair, from auto glass to structural components, meets stringent functionality and aesthetics criteria. Structural integrity checks using advanced technologies like 3D laser scanning and CAD software detect minor defects. Post-repair testing includes frame alignment, suspension, and body panel evaluations with advanced diagnostic tools, guaranteeing safe, reliable vehicles ready for daily driving.

Tesla vehicles are renowned for their cutting-edge technology and innovative design, but ensuring structural integrity after repairs is paramount. This article delves into Tesla’s rigorous repair quality control processes, exploring industry-leading standards and advanced methods for structural integrity checks. We uncover the technologies employed to maintain the iconic vehicle’s safety and performance, as well as post-repair testing protocols designed to guarantee longevity. Understanding these practices empowers owners and mechanics alike.

- Understanding Tesla Repair Quality Control Standards

- Structural Integrity Checks: Methods and Technologies

- Ensuring Longevity: Post-Repair Testing Protocols

Understanding Tesla Repair Quality Control Standards

Tesla Repair Quality Control (TQQC) standards are designed to uphold the company’s reputation for innovation and quality in luxury vehicle repair. These rigorous protocols ensure that every component, from auto glass repair to intricate structural repairs after a fender bender, meets Tesla’s stringent criteria for both functionality and aesthetics. TQQC involves a multi-step process, including meticulous visual inspections, advanced diagnostic testing, and performance validation, all aimed at restoring vehicles to their pre-incident condition.

The focus on structural integrity checks is a cornerstone of TQQC. This involves assessing the alignment, stability, and overall strength of various vehicle parts after repairs. By adhering to these standards, Tesla guarantees that its vehicles not only drive smoothly but also maintain their safety features and longevity, setting them apart in the competitive luxury car market.

Structural Integrity Checks: Methods and Technologies

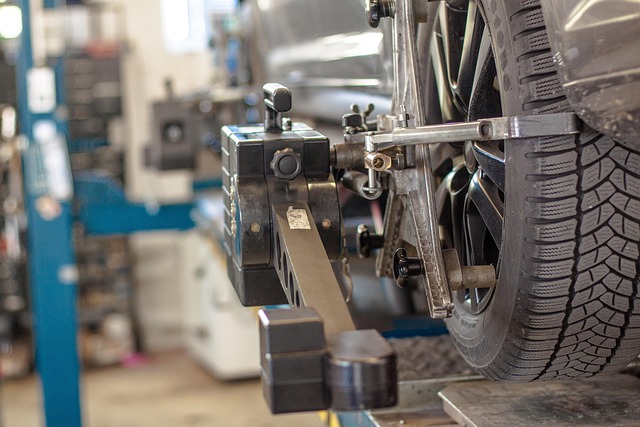

Structural integrity checks are a crucial part of Tesla repair quality control, ensuring that vehicles return to the road safely and reliably. These rigorous inspections involve a combination of advanced methods and technologies designed to detect even the smallest defects or discrepancies in a vehicle’s structural components. Modern techniques such as 3D laser scanning and computer-aided detection (CAD) software enable precise measurements and comparisons, allowing technicians to identify any deviations from the original manufacturing specifications.

When it comes to assessing structural integrity, Tesla repairs often involve specialized equipment for detailed examinations. This includes advanced imaging systems capable of revealing hidden damage, such as cracks or corrosion, that may not be immediately apparent. Additionally, non-destructive testing methods like ultrasonic and magnetic particle inspections are employed to verify the condition of critical parts without causing further harm. These comprehensive approaches, integrated within Tesla’s repair quality control processes, guarantee that every vehicle undergoes thorough scrutiny, fostering confidence in both the manufacturer’s and body shop services’ capabilities.

Ensuring Longevity: Post-Repair Testing Protocols

After a Tesla vehicle undergoes repair, ensuring its structural integrity is paramount to guarantee longevity on the road. Post-repair testing protocols play a critical role in this process. These rigorous checks are designed to verify that every component has been accurately restored and meets the brand’s stringent quality standards.

The testing involves a comprehensive evaluation of various systems, including frame alignment, suspension components, and body panels. Advanced diagnostic tools are employed to assess any discrepancies or remaining damage. This meticulous approach ensures that vehicles leaving the collision center or repair shop are safe, reliable, and ready to endure the challenges of daily driving for years to come, solidifying Tesla’s reputation for exceptional vehicle repair quality control.

Tesla repair quality control is a multifaceted process designed to ensure structural integrity and longevity of repaired vehicles. By adhering to stringent standards, employing advanced methods like 3D scanning and utilizing rigorous post-repair testing protocols, Tesla maintains its reputation for innovative and reliable vehicle repairs. Integrating these practices guarantees that each fixed vehicle not only meets but exceeds original equipment quality, providing owners with peace of mind on the road.