Tesla is revolutionizing repair quality control through artificial intelligence (AI) and machine learning, enhancing precision and efficiency in auto body work. These advanced systems predict issues, adapt to each vehicle, and improve visual inspections, reducing human error and streamlining operations. Tesla's commitment to sustainability also drives eco-friendly repair practices, using green materials and recycling programs to minimize the environmental impact of collision repairs, while aligning with their lifecycle sustainability goals.

The future of Tesla repairs is here, with innovative systems revolutionizing quality control. This article explores cutting-edge advancements in AI and machine learning, enhancing accuracy and safety through advanced diagnostics. We delve into sustainable practices, focusing on eco-friendly materials and processes that benefit both the environment and vehicle performance. As Tesla continues to evolve, these developments promise superior repair outcomes, ensuring your electric vehicle returns to peak condition while minimizing its ecological footprint.

- Evolving Technology: AI and Machine Learning in Tesla Repair Quality Control

- Enhanced Safety Features: The Role of Advanced Diagnostics in Ensuring Repair Accuracy

- Sustainable Practices: Eco-Friendly Materials and Processes for Better Tesla Repairs

Evolving Technology: AI and Machine Learning in Tesla Repair Quality Control

The future of Tesla repair quality control is being reshaped by advancements in artificial intelligence (AI) and machine learning. These technologies are revolutionizing how Tesla maintains and repairs its vehicles, setting new standards for auto body work precision and efficiency. AI-powered systems can analyze vast datasets to predict potential issues before they occur, enabling proactive maintenance. In the event of a repair, machine learning algorithms adapt to each unique vehicle, ensuring that every step of the process—from assessing damage in car dent repair to final quality checks—meets Tesla’s stringent criteria.

Furthermore, AI enhances visual inspection and identification processes, allowing for more accurate assessments of cosmetic damages like those encountered in auto body work. By integrating these intelligent systems into repair quality control, Tesla aims to streamline operations, reduce human error, and maintain the exceptional craftsmanship that has become synonymous with its brand, all while adhering to evolving industry standards and customer expectations.

Enhanced Safety Features: The Role of Advanced Diagnostics in Ensuring Repair Accuracy

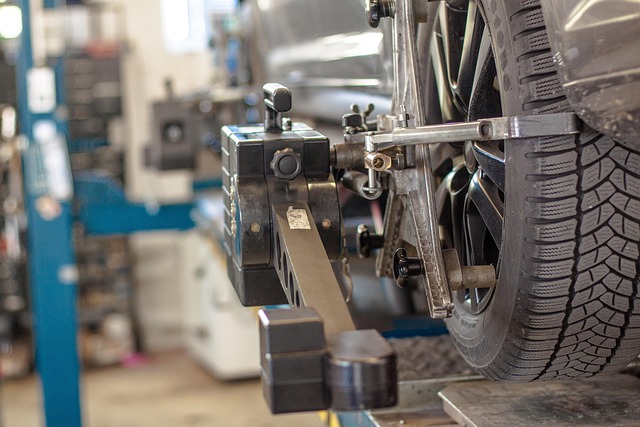

In the ever-evolving landscape of Tesla repair quality control, enhanced safety features are playing a pivotal role by driving the need for advanced diagnostics. As vehicles become increasingly complex with integrated technology, ensuring precise repairs is more critical than ever. Advanced diagnostic tools allow auto body shops to accurately identify and address issues within the vehicle’s electrical systems, software, and hardware—key components in Tesla models. These technologies not only enhance repair accuracy but also streamline the process, reducing the time required for troubleshooting and customer wait times.

With safety as a top priority, Tesla continues to invest in innovative solutions that improve vehicle performance and reliability. By integrating advanced diagnostics into their repair quality control systems, auto body shops can better serve Tesla owners, providing high-quality repairs that meet the brand’s rigorous standards. This shift towards sophisticated diagnostic methods is transforming the auto maintenance industry, especially within specialized vehicle bodywork services tailored to Tesla vehicles.

Sustainable Practices: Eco-Friendly Materials and Processes for Better Tesla Repairs

As Tesla continues to lead the electric vehicle revolution, it’s natural that the focus on sustainability extends to the realm of repairs and maintenance. Sustainable practices in Tesla repair quality control are no longer a niche concern but a necessity, with eco-friendly materials and processes becoming integral to better car restoration. This shift not only reduces the environmental impact of collision repair shops but also aligns with Tesla’s commitment to sustainability throughout its product lifecycle.

One notable aspect is the adoption of green materials for dent removal and other repair procedures. Biodegradable compounds are increasingly being used in place of traditional, often toxic chemicals. Furthermore, recycling programs for various components are being implemented, diverting waste from landfills and reducing the need for new raw materials. These practices not only contribute to a cleaner environment but also enhance the overall quality control in Tesla repairs by ensuring that every step of the process is as eco-friendly as possible.

The future of Tesla repair quality control looks promising with advancements in AI, machine learning, advanced diagnostics, and eco-friendly materials. Integrating these technologies not only enhances safety features but also ensures precision repairs, aligning with Tesla’s commitment to sustainability. As the brand evolves, maintaining high repair quality control standards will be key to satisfying its global customer base and solidifying its position as an industry leader.