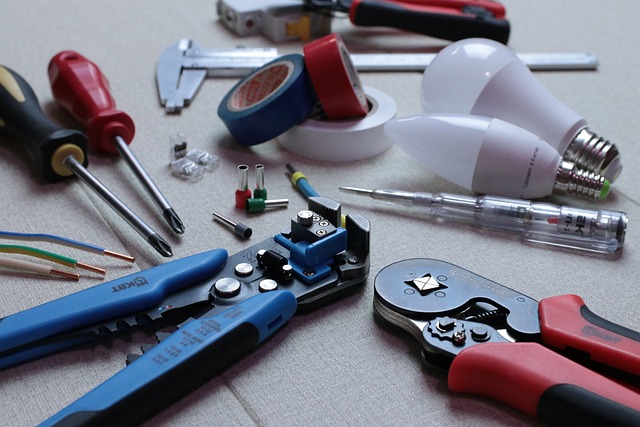

Tesla is leveraging artificial intelligence (AI) and machine learning (ML) to revolutionize its repair quality control, ensuring superior vehicle restoration standards. AI algorithms predict potential issues based on historical data, while ML models analyze vast datasets for trend identification and defect detection, even subtle ones. This technology streamlines processes, minimizes human error, and speeds up repairs, maintaining Tesla's reputation for high-quality work and keeping pace with demand. Integration brings faster turnaround times, cost reduction, and improved accuracy in auto repair, as AI and ML adapt through continuous learning to support evolving Tesla models and techniques.

“The future of Tesla repair is being reshaped by innovative technologies, significantly enhancing quality control processes. This article delves into cutting-edge advancements that are revolutionizing the automotive industry. From AI and machine learning algorithms to augmented reality (AR) visualization and the Internet of Things (IoT), these developments promise unparalleled precision and efficiency in Tesla repairs.

We explore how AI ensures consistent quality, AR provides real-time guidance for technicians, and IoT sensors enable predictive maintenance, collectively fostering superior repair outcomes.”

- Advancements in AI and Machine Learning for Quality Control

- – The role of AI in Tesla repair quality control

- – Benefits of machine learning algorithms in identifying defects

Advancements in AI and Machine Learning for Quality Control

The future of Tesla repair quality control is closely tied to advancements in artificial intelligence (AI) and machine learning (ML). These cutting-edge technologies are transforming various industries, and automotive repair is no exception. By leveraging AI and ML algorithms, Tesla can streamline its quality control processes, ensuring consistent and superior vehicle restoration standards. For instance, AI-powered inspection systems can detect even the subtlest defects in auto frame repair, enhancing precision and safety.

Moreover, these systems can learn and adapt over time, improving their effectiveness in auto detailing and overall repair accuracy. The integration of ML models allows for intelligent data analysis, enabling Tesla to identify trends, common issues, and areas for improvement within its repair operations. This technology-driven approach promises to revolutionize the way Tesla maintains quality control, ultimately elevating customer satisfaction with seamless vehicle restoration services.

– The role of AI in Tesla repair quality control

The integration of Artificial Intelligence (AI) is set to transform Tesla’s repair quality control systems, enhancing precision and efficiency in vehicle repair services. AI algorithms can analyze vast amounts of data from past repairs, design updates, and production processes to predict potential issues before they occur. This predictive capability allows for proactive quality control measures, ensuring that every component meets the brand’s stringent standards. By learning from previous car restoration cases, AI models can identify subtle variations in materials, techniques, or assembly methods that might impact final repair quality.

Moreover, AI-driven quality control systems can streamline the inspection process by automating repetitive tasks. Computer vision algorithms can inspect vehicle paint repairs with incredible accuracy, identifying even microscopic imperfections. This not only reduces human error but also accelerates the entire repair process, allowing Tesla to maintain its reputation for high-quality, reliable vehicle repair services and car restoration while keeping up with growing demand.

– Benefits of machine learning algorithms in identifying defects

Machine learning algorithms are poised to revolutionize Tesla repair quality control by offering unprecedented precision and efficiency in identifying defects. These advanced systems can analyze vast amounts of data from visual inspections, sensor readings, and historical records to detect even subtle anomalies that might be missed by human inspectors. By leveraging machine learning, auto repair shops and collision centers can achieve higher levels of consistency and accuracy in their vehicle restoration processes.

The integration of machine learning into Tesla repair quality control systems brings several benefits, including faster turnaround times, reduced costs, and improved overall repair quality. These algorithms can continuously learn from new data inputs, adapting to evolving vehicle models and repair techniques. This adaptability ensures that the quality control processes remain relevant and effective as Tesla continues to innovate its vehicle designs and engineering. Moreover, by automating defect identification, machine learning frees up human resources to focus on more complex tasks, enhancing the overall efficiency of the auto repair shop or collision center.

As we look towards the future, the integration of advanced AI and machine learning technologies promises to revolutionize Tesla repair quality control. These innovative systems will not only enhance defect detection accuracy but also streamline the entire repair process, ultimately improving customer satisfaction with more efficient and reliable service. By leveraging the power of AI, Tesla can maintain its reputation for cutting-edge technology and ensure that its vehicles meet the highest standards of repair quality.